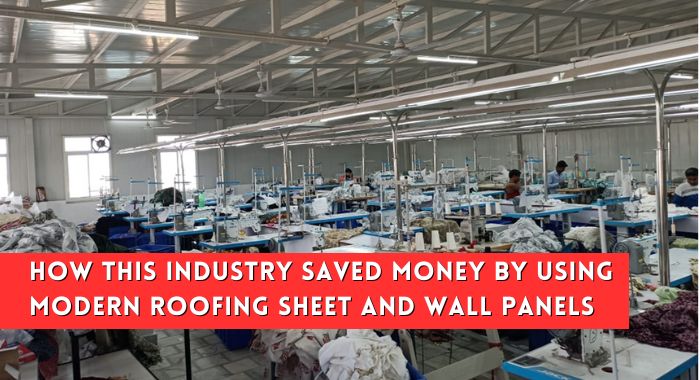

Modern Industrial Building Construction: Mr. Rathore’s state of Art factory shed with PEB Roofing Shed in Kaladera, Jaipur

The name Mr Rathore may not be as familiar to the general populace as some of the other names of prominent businessmen, but in the world of manufacturing, this is a name that commands a lot of respect. Mr Rathore is a serial entrepreneur who has made significant contributions in the industrial construction revolution in India.

Recently, Mr Rathore has embarked on a new project – setting up a Dairy processing factory in Kaladera, Jaipur. This new factory will be in partnership with AMUL, and it will be used for processing milk for them. With the scale and scope of operations of Amul, this project was certain to be a revolutionary step forward in the manufacturing industry. However, the choice of roofing materials for such a construction of factory shed posed quite a few problems. Mr. Rathore wanted a viable solution that would provide the industrial building with good looks, protection from heat, as well as speed up the construction process.

To address this challenge, Mr Rathore consulted with Pronto panels, and they came up with a solution that was perfectly suited to his needs. Pronto provided the Amul team with insulated PUF panel roofing sheets, known as Pronto Panels, which paint-proof, heat-proof and insulated the building, all in a single application.

The installation of these panels provided incredible benefits for Mr. Rathore. Firstly, they got a professional roofing and wall product which was heat proof as well as pre-painted. Secondly, the project budget was greatly reduced when compared to brick and mortar construction. And finally, the interiors of the new factory floor looked world class while temperature within the factory was maintained at optimal levels, ensuring the purity of the milk products.

Mr Rathore’s foray into the manufacturing sector, coupled with the robust solutions provided by Pronto Panels, has resulted in a modern, well-equipped, and visually-pleasing milk processing factory shed. With this revolutionary step, there is no doubt that Mr. Rathore is set to make an even bigger name for himself in the industrial space.

Mr Rathore gave an Ultimate Guide to Choosing the Perfect Roofing Sheet for Your Factory Shed. Here are some excerpts:-

When it comes to constructing a factory shed, one of the most important decisions you’ll make is choosing the right roofing sheet. Your roofing choice can have a significant impact on the overall durability, efficiency, and aesthetic appeal of your building. With so many different roofing materials and styles available, it can be overwhelming to decide which one is best for your needs. We also decided to explore the various factors to consider when selecting a roofing sheet, including durability, cost, energy efficiency, and more. We considered some of the most popular roofing materials, such as metal corrugated roofing, PuF roofing sheet, cement sheet, to help you make an informed decision. We summarized our experience in this guide so that you’ll be well-equipped to choose the perfect roofing sheet for your factory shed, ensuring that your building is both functional and visually appealing.

Factors to consider when choosing roofing sheets

When choosing a roofing sheet for your factory shed, there are several factors to consider. The following are some of the most important factors to keep in mind:

### Durability

One of the most important factors to consider when choosing a roofing sheet for your factory shed is durability. The roofing sheet you choose should be able to withstand harsh weather conditions, such as heavy rain, strong winds, and extreme temperatures. You should also consider the lifespan of the roofing sheet, as you don’t want to have to replace it too often.

### Cost

Another important factor to consider when choosing a roofing sheet for your factory shed is cost. You’ll want to choose a roofing sheet that fits within your budget, but you should also consider the long-term cost of the sheet. A more expensive roofing sheet may be more durable and have a longer lifespan, which could save you money in the long run.

### Energy Efficiency

Energy efficiency is becoming increasingly important when it comes to roofing sheets. A roofing sheet that is energy-efficient can help to reduce your energy bills and make your factory shed more environmentally friendly. There are several roofing materials that are known for their energy efficiency, such as metal and polycarbonate.

Types of roofing sheets and their characteristics

There are several types of roofing sheets available on the market, each with its own set of characteristics. The following are some of the most popular types of roofing sheets:

### Metal roofing sheets

Metal roofing sheets are one of the most popular roofing materials for factory sheds. They are durable, lightweight, and relatively easy to install. Metal roofing sheets are also available in a range of colors and styles, making them a versatile option for any factory shed.

Advantages of metal roofing sheets:

– Very low cost

– Lightweight and easy to install

– Available in a range of colors and styles

Disadvantages of metal roofing sheets:

– Get very hot in summers.

– Start leaking in couple of heavy rain

– Can be prone to denting if hit by heavy objects

– Can be prone to rust if not properly maintained

– Need regular maintenance

PuF roofing sheets – A Modern Alternative

PuF roofing sheets are a modern alternative to traditional roofing materials. They are made from a combination of polyurethane foam and steel, making them lightweight, durable, and energy-efficient. PuF roofing sheets are also available in a range of colors and styles, making them a versatile option for any factory shed. Brands like Pronto provide international scale quality at affordable prices.

Advantages of PuF roofing sheets:

– Lightweight and easy to install

– Excellent insulation properties

– Energy-efficient

– Resistant to impact and weather damage

– Available in a range of colors and styles

Disadvantages of PuF roofing sheets:

– Can be more expensive than some other roofing materials

– Not as widely available as some other roofing materials

Cost of PuF roofing sheet

The cost of PuF roofing sheets can vary depending on several factors, such as the size of your factory shed and the thickness of the roofing sheet. However, at first glance, they may seem more expensive than other types of roofing materials. This is because PUF roofing sheets have superior insulation properties and durability. A quality brand like Pronto starts at 106/SqFt.

Here’s a secret: the overall cost of construction with PUF panels is equivalent to that of metal roofing sheets. This is because Pronto sheets are very strong and require less structural support. The savings in the cost of the structure cancels out the additional cost of the PUF sheets.

Conclusion – choosing the right roofing sheet for your factory shed

Choosing the right roofing sheet for your factory shed is an important decision that should not be taken lightly. By considering factors such as durability, cost, and energy efficiency, you can make an informed decision that meets your needs and fits within your budget. Write above content as if expressed by Mr Rathore who recently constructed a new factory shed using Pronto PuF roofing sheets.