How This Industry saved money by using Modern Roofing sheet and Wall panels

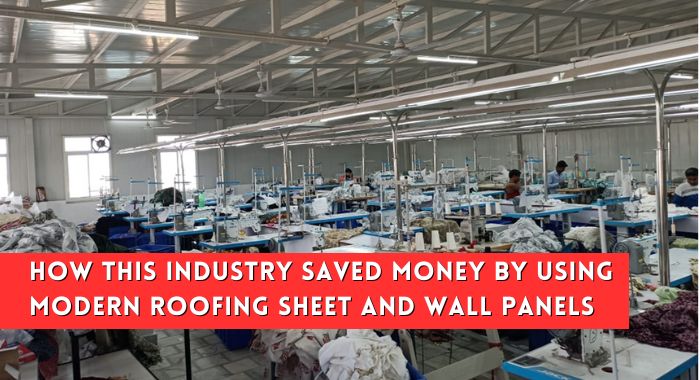

In today’s rapidly evolving world, construction materials and techniques are constantly advancing to meet the growing demands of modern infrastructure. Pronto, a leading provider of PUF panels for roof and wall construction, has recently completed a remarkable project in the Kanakpura Industrial Area, Jaipur. This project, undertaken for Mr. Vaibhav Jhalani, owner of a garment manufacturing company, showcases how Pronto’s innovative roofing sheet have revolutionized the construction industry by providing efficient and sustainable solutions to space problems. This article depicts into the challenges faced by Mr. Jhalani, the solutions offered by Pronto, and the significant benefits derived from their implementation.

Mr. Jhalani’s garment factory operated under a dilapidated tin shed roof, which resulted in numerous difficulties for the workers. Harsh heat during summer months, water leakage during rainy seasons, and the subsequent damage to their stock had a detrimental impact on productivity. Moreover, the high cooling costs and the unsightly appearance of the workspace due to the worn-out roofing added to the overall challenges faced by the textile company.

Recognizing the need for a composite solution, Mr. Jhalani decided that he must find another factory. Luckily, he found empty space on the terrace of his old building which upon which he could expand his factory by adding an additional floor to it. However, upon consulting with the structural engineers, he found out that the building was not in a position to support the weight of an additional floor since the traditional RCC based construction (brick and mortar) is quite bulky.

In his search for a Lightweight as well as a Strong and Durable option, he thus came across Pronto Panels for the construction of an entire floor on the existing old building. The PUF (Polyurethane Foam) panels offered by Pronto proved to be an ideal alternative to traditional RCC-based construction, as they significantly reduced the weight load on the structure. To illustrate this in a better way, the average density of a brick wall is roughly around 1800 to 2100 kg/m3, whereas, that of Pronto PUF Panel is at 40 kg/m3, which is staggeringly low compared to the weight of a brick wall. The lightweight nature of the panels thus made it possible to construct an additional floor without compromising the integrity of the building. This innovation allowed Mr. Jhalani to expand his textile operations, overcoming the limitations posed by the existing structure.

Moreover, construction from Pronto Panels can be done in comparatively very less time since the panels are precut from the factory itself as per the requirements of the project, leaving the job of only installation to be done on site which hardly takes a few days. The client is thus saved from both the hassle and increased labor costs of getting an RCC based construction which might go on for months. Pronto also offers a wide range of readymade rooms and cabins for small scale construction projects which add to the cost and time savings. A few examples are as follows:

The implementation of Pronto Panels brought about a remarkable transformation in Mr. Jhalani’s factory, providing a multitude of benefits that changed the work environment and construction efficiency. The high insulating capacity of these panels resulted in a substantial reduction in electricity consumption for cooling purposes. As a result, the workspace became more comfortable, enabling workers to be more productive even during scorching summers. Pronto Panels’ ability to insulate against heat not only enhanced the working conditions but also significantly reduced cooling costs, optimizing energy usage and promoting sustainability.

Additionally, the interlocking joint mechanism of the panels effectively prevented any water seepage through the roof, safeguarding the textile stock from damage caused by rainfall. This feature eliminated one of the primary concerns Mr. Jhalani faced in the past, enhancing the reliability and durability of his operations. The waterproofing capability of Pronto Panels ensured the preservation of valuable textile stock, reducing losses and increasing overall productivity.

Furthermore, Pronto’s Roof Panels exhibited exceptional load-bearing capacity, allowing them to support the entire electrical system, including fans and lighting. This reduced the cost of metallic support structure, significantly bringing down the overall construction expenses. The strength and durability of Pronto Panels therefore provides a reliable foundation for the electrical infrastructure.

Is Pronto an Expensive Alternative?

Initially Mr. Jhalani was skeptical on choosing Pronto for Roofing as metal sheet roofing is available @ Rs. 50 per sq. ft. whereas, Pronto’s PUF Panels are available @ Rs. 106 per sq. ft. . But, he was soon convinced when he got to know that there is an additional saving of about Rs. 50 to 60 per sq. ft. in the support structure (purlins) since, traditional metal sheet roofing, being unable to support its own weight, requires a lot more of underlying support through metal beams (purlins); which is not required in the case of PUF Panels.

Therefore, the net total cost comes out to roughly be the same for both the alternatives, but along with a lot more advantages in the case of Pronto PUF Panels; hence, it became the obvious choice to proceed with for Mr. Jhalani.

For the Walls, using RCC to construct them was clearly out of question for him as a traditional RCC Wall works out to be roughly @ Rs. 200 per sq. ft. (including plaster and paint) which is far more than Pronto Wall Panels available @ Rs. 110 per sq. ft., this saving in cost is largely because of reduced labor requirement as well as no need of additional plastering or paint job on Pronto Wall Panels since they come ready-to-install, tailored according to the customer’s needs straight from the factory.

Thus, Mr. Jhalani rather makes a profit by choosing Pronto to construct his factory. Not to mention, the energy savings he will be making in the long run due to the panel’s exceptional insulating capabilities.

To obtain a more detailed insight into how choosing Pronto can lead to enormous cost savings in YOUR building project, visit PRONTO COST CALCULATOR LINK

In conclusion, the success of Pronto’s project at the Kanakpura Industrial Area in Jaipur, executed for Mr. Vaibhav Jhalani’s textile factory, serves as a testament to the company’s commitment to providing state-of-the-art construction materials and solutions. Pronto Panels offer a host of features such as insulation, fireproofing, waterproofing, and soundproofing, all while being highly durable and strong, and not bulky. These panels represent an optimal choice for any construction project, providing long-lasting performance and best value for money by elimination of additional metal support structures and reduced cooling costs, making them a cost-efficient choice for construction projects, providing the best value for money.

With Pronto Panels, businesses and industries can experience enhanced productivity and improved energy efficiency. By addressing the challenges of heat, water leakage, and increased costs associated with traditional construction methods, Pronto has revolutionized the way factories are designed and constructed, thus, transforming numerous workspaces.